Difference between revisions of "Timeline of titanium"

From Timelines

(→Visual data) |

|||

| Line 1: | Line 1: | ||

| − | This is a '''timeline of | + | This is a '''timeline of {{w|titanium}}''', attempting to describe important events related to the discovery, science and industrial development of the metal. |

==Big picture== | ==Big picture== | ||

| Line 40: | Line 40: | ||

| 1925 || || Titanium of very high purity is made in small quantities when {{w|Anton Eduard van Arkel}} and {{w|Jan Hendrik de Boer}} discover the iodide, or [[w:crystal bar process|crystal bar]], process, by reacting with iodine and decomposing the formed vapours over a hot filament to pure metal.<ref>{{cite journal |last=van Arkel |first=A. E. |authorlink=Anton Eduard van Arkel |author2=de Boer, J. H. |title=Preparation of pure titanium, zirconium, hafnium, and thorium metal |journal={{w|Zeitschrift für anorganische und allgemeine Chemie}} |date=1925 |volume=148 |pages=345–50 |doi=10.1002/zaac.19251480133}}</ref><ref name="Titanium: Physical Metallurgy, Processing, and Applications"/><ref name="ssssssssss"/> || {{w|Netherlands}} | | 1925 || || Titanium of very high purity is made in small quantities when {{w|Anton Eduard van Arkel}} and {{w|Jan Hendrik de Boer}} discover the iodide, or [[w:crystal bar process|crystal bar]], process, by reacting with iodine and decomposing the formed vapours over a hot filament to pure metal.<ref>{{cite journal |last=van Arkel |first=A. E. |authorlink=Anton Eduard van Arkel |author2=de Boer, J. H. |title=Preparation of pure titanium, zirconium, hafnium, and thorium metal |journal={{w|Zeitschrift für anorganische und allgemeine Chemie}} |date=1925 |volume=148 |pages=345–50 |doi=10.1002/zaac.19251480133}}</ref><ref name="Titanium: Physical Metallurgy, Processing, and Applications"/><ref name="ssssssssss"/> || {{w|Netherlands}} | ||

|- | |- | ||

| − | | 1932 || || | + | | 1932 || || Luxembourgish {{w|metallurgist}} {{w|William Justin Kroll}} proves that titanium can be produced by reducing titanium tetrachloride (TiCl4) with {{w|calcium}}.<ref name="Materials Handbook: A Concise Desktop Reference">{{cite book |last1=Cardarelli |first1=François |title=Materials Handbook: A Concise Desktop Reference |url=https://books.google.com.ar/books?id=koRjDwAAQBAJ&pg=PA397&lpg=PA397&dq=%22Kroll+process%22+%22in+1930..1950%22&source=bl&ots=ykHwp_mfvT&sig=lOkEW2vXt7aAqiCibY9U9p3nG0I&hl=en&sa=X&ved=2ahUKEwiWp7SH_7jcAhUIDZAKHfCKBkUQ6AEwAHoECAAQAQ#v=onepage&q=%22Kroll%20process%22%20%22in%201930..1950%22&f=false}}</ref> The process, known today as {{w|Kroll process}}, would replace the {{w|Hunter process}} for almost all commercial production.<ref>Holleman, A. F.; Wiberg, E. "Inorganic Chemistry" Academic Press: San Diego, 2001. {{ISBN|0-12-352651-5}}.</ref> || |

|- | |- | ||

| − | | 1937 || || | + | | 1937 || || {{w|William Justin Kroll}} invents the magnesium reduction process (reducing titanium tetrachloride with {{w|magnesium}}) by utilizing an inert {{w|argon}} atmosphere to protect the titanium metal from reoxidizing. Kroll is credited with developing the technology that would lead eventually to the large-scale commercialization of titanium metallurgy.<ref name="gsdgds"/><ref name="ssssssssss"/> || |

|- | |- | ||

| 1938 || || {{w|William Justin Kroll}}, at the Bureau of Mines in Albany, Oregon, produces the first display of cold ductile titanium in the United States. The work of W.J. Kroll is considered the start of the present large-scale titanium industry.<ref name="Titanium: Physical Metallurgy, Processing, and Applications"/> || {{w|United States}} | | 1938 || || {{w|William Justin Kroll}}, at the Bureau of Mines in Albany, Oregon, produces the first display of cold ductile titanium in the United States. The work of W.J. Kroll is considered the start of the present large-scale titanium industry.<ref name="Titanium: Physical Metallurgy, Processing, and Applications"/> || {{w|United States}} | ||

Revision as of 17:26, 24 July 2018

This is a timeline of titanium, attempting to describe important events related to the discovery, science and industrial development of the metal.

Contents

Big picture

| Time period | Development summary |

|---|---|

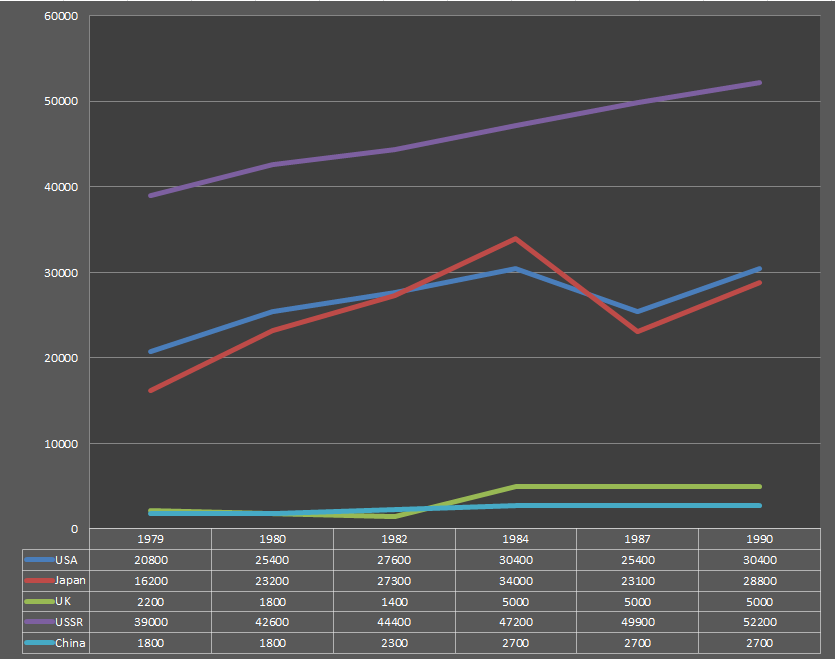

| 1950s–1960s | Titanium has a relatively short production history. The first commercial quantities of titanium are produced at around 1950.[1] In the early 1950s, a number of companies enter the titanium business in the United States, with strong government support.[1] In the 1950s and 1960s, the Soviet Union pioneer the use of titanium in military and submarine applications[2] (Alfa class and Mike class)[3] as part of programs related to the Cold War.[4] |

| 1980s | A rise in titanium shipments occur in the decade, largely in part due to the United States military buildup and the increase of aerospace and other nonmilitary uses.[1] |

| 1990s | Early in the decade, with the ending of the Cold War and the collapse of the Soviet Union, defense expenditures decline and the military demand for titanium decreases.[1] |

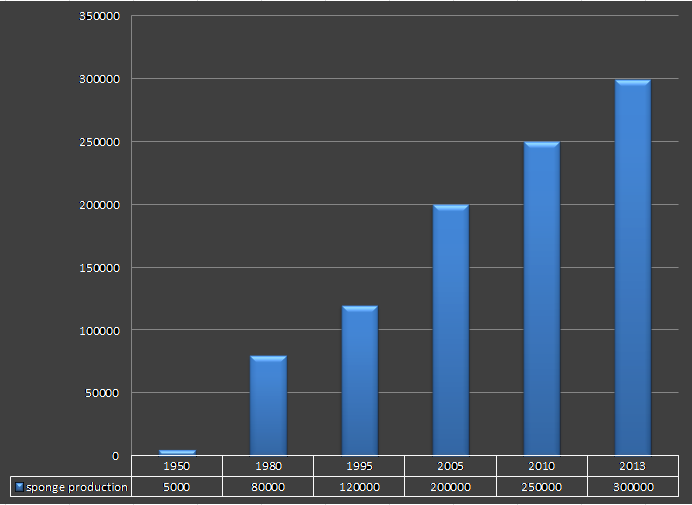

| 2000s< | China emerges as a global player in titanium sponge production.[5] |

Visual data

Full timeline

| Year | Event type | Details | Country/region |

|---|---|---|---|

| 1790 | British Reverend William Gregor in England discovers the element titanium.[1][6][7][8] | United Kingdom | |

| 1791 | William Gregor presents a description and chemical composition of some black magnetic sands found on the southern Cornish coast. Gregor's analysis of the black sand correspond roughly to that of mineral ilmenite (FeTiO3).[1] | United Kingdom | |

| 1795 | German chemist Martin Heinrich Klaproth identifies the oxide of an unknown element, the same as the one reported by Gregor. Klaproth names the element titanium after the Titans, the powerful sons of the earth in Greek mythology.[9][10][11][12] | Germany | |

| 1887 | L.F. Nilson and O. Peterson obtain a product of 97.4% purity by reducing titanium tetrachloride with sodium in an airtight steel cylinder.[1] | ||

| 1906 | M.A. Hunter at General Electric in the United States produces the first pure titanium metal.[1] | United States | |

| 1910 | New Zelander metallurgist Matthew Hunter achieves the production of pure metallic titanium (99.9%). The later called Hunter process is the first industrial process to produce pure ductile metallic titanium.[13][5] | ||

| 1925 | Titanium of very high purity is made in small quantities when Anton Eduard van Arkel and Jan Hendrik de Boer discover the iodide, or crystal bar, process, by reacting with iodine and decomposing the formed vapours over a hot filament to pure metal.[14][1][5] | Netherlands | |

| 1932 | Luxembourgish metallurgist William Justin Kroll proves that titanium can be produced by reducing titanium tetrachloride (TiCl4) with calcium.[15] The process, known today as Kroll process, would replace the Hunter process for almost all commercial production.[16] | ||

| 1937 | William Justin Kroll invents the magnesium reduction process (reducing titanium tetrachloride with magnesium) by utilizing an inert argon atmosphere to protect the titanium metal from reoxidizing. Kroll is credited with developing the technology that would lead eventually to the large-scale commercialization of titanium metallurgy.[13][5] | ||

| 1938 | William Justin Kroll, at the Bureau of Mines in Albany, Oregon, produces the first display of cold ductile titanium in the United States. The work of W.J. Kroll is considered the start of the present large-scale titanium industry.[1] | United States | |

| 1946 | A United States Bureau of Mines publication describes a Kroll unit capable of making 7kg batches of good-quality titanium powder by magnesium reduction, followed by acid leaching to remove the excess magnesium and MgCl2.[1] | United States | |

| 1947 | P.R. Mallory Company begins work on the powder metallurgy of titanium under the United States Navy sponsorship.[1] | United States | |

| 1948 | Titanium sponge production begins at Imperial Chemical Industries in the United Kingdom.[1] | United Kingdom | |

| 1948 | The first commercial titanium is produced. The total production that year is just over 1800 kg.[1] | ||

| 1949 | The United States Bureau of Mines reports the successful operation of a magnesium-reduction unit for making 40kg batches of titanium.[1] | United States | |

| 1949 | The first titanium for actual flight is ordered from Remingtom Arms by the Douglas Company.[1] | United States | |

| 1949 | A semicommercial titanium-melting facility is started by Allegheny Ludlum Steel Corporation in the United States.[1] | United States | |

| 1950 | American steel producer Republic Steel organizes a titanium division to produce mill products.[1] | United States | |

| 1950 | Organization | The Titanium Metals Corporation of America (TMCA) is organized by Allegheny Ludlum Steel Corporation and the National Steel Company. TMCA would become the first fully integrated company for producing titanium from ore to finished products.[1] | United States |

| 1950 | Titanium starts being produced in the Soviet Union.[1] | ||

| 1951 | The Mallory-Sharon Titanium Corporation is organized by P.R. Mallory Company and Sharon Steel Corporation.[1] | United States | |

| 1951 | The United States National Lead operates the Bureau of Mines titanium sponge plant, and at around the same time, constructs pilot plants for sponge.[1] | United States | |

| 1952 | The United States Bureau of Mines reports the removal of magnesium and magnesium chloride from titanium sponge by vacuum distillation.[1] | United States | |

| 1952 | A pilot unit created in 1947 at DuPont expands production to 800,000 kg of titanium sponge per year.[1] | United States | |

| 1954 | American corporation Dow Chemical Company starts titanium sponge production.[1] | United States | |

| 1954 | Titanium sponge production begins in Japan, with two companies, Osaka Titanium and Toho Titanium, reaching relatively large capacities by 1954.[9] | Japan | |

| 1955 | Imperial Chemical Industries becomes the principal European manufacturer of titanium and titanium alloy mill products, with a production oj 1.5 million kg in the year.[1] | United Kingdom | |

| 1955 | The production of titanium grows to 9000kg, up from 1800kg in 1948.[1] The United States is the world's leading producer of titanium metal at the time.[13] | ||

| 1956 | Union Carbide Corporation begins production of titanium sponge.[1] | United States | |

| 1958 | National Distillers and Chemical Corporation begins production of titanium sponge.[1] | United States | |

| 1966 | Oregon Metallurgical Corporation begins production of titanium sponge.[1] | United States | |

| 1967 | The first patent to use hydrogenated titanium in a sintering process is filed.[17] | ||

| 1970 | The process of "decomposition powder metallurgy" is first reported as a means to produce titanium alloys and metal matrix composites via hot pressing.[17] | ||

| 1979 | The Soviet Union becomes the world's largest titanium sponge producer.[9] | ||

| 1980 | Teledine Wah Chang Albany begins production of titanium sponge.[1] | United States | |

| 1981 | D-H Titanium Company begins production of titanium sponge.[1] | United States | |

| 1982 | The Western Zirconium Company begins production of titanium sponge.[1] | United States | |

| 1986 | Production | The worldwide titanium ingot capacity excluding the Communist bloc increases to approximately 90,000kg. In the same year, it is estimated that USSR produced an additional 36,000 kg.[1] | |

| 1993 | Application | The Fukuoka Dome is built in Japan. It is covered with titanium roofing.[9] | Japan |

| 1999 | Application | Gibraltar releases the world's first titanium coin for the millennium celebration.[18] | Gibraltar |

| 2005 – 2008 | Production | Titanium sponge production increased from 104,000 to 176,000 tonnes in the period. The growth is partly driven by a surge in demand from the aerospace sector, but also by growing demand for titanium in chemical plant in China. Chinese output of titanium sponge increased fivefold between 2005 and 2008.[19] | |

| 2006 | Production | According to data, the world's largest producer, Russian-based VSMPO-AVISMA, is estimated to account for about 29% of the world market share.[20] | Russia |

| 2008 | Demand | A sharp decline in titanium demand is caused by the global economic slowdown and delays in the production of high-titanium content aircraft such as the A380 and B787.[19] | |

| 2009 | Production | As of date, production of titanium sponge is confined to six countries, in order of output, China, Japan, Russia, Kazakhstan, United States and Ukraine.[19] | China, Japan, Russia, Kazakhstan, United States and Ukraine |

| 2009 | Demand | The global market for titanium mill products is about 100,000 tonnes compared with 130,000 in 2008.[19] | |

| 2010 | Production | China stands as the main engine for growth, and production of titanium grows strongly with several new large-scale sponge plants under construction.[19] | China |

| 2010 | Infrastructure | As of date, There are 18 companies producing titanium sponge, of which nine are in China, compared with just two plants a decade ago. In 2010, titanium ingot melting capacity is nominally 340,000 tonnes, 85% of which is located in Russia, the United States, Japan and China.[19] | |

| 2015 | Production | India opens titanium sponge plant at Chavara in Kerala, and becomes the seventh country in the world producing titanium sponge commercially.[21] | India |

| 2017 | Financial | The global titanium powder market is valued at US$3230 million in the year.[22] Also, the global Titanium Aluminide Alloy market is valued at US$ 140 million.[23] | |

| 2028 | Financial | Analysts predict the global market size of titanium powder will reach US$3450 million by the end of that year.[22] |

Meta information on the timeline

How the timeline was built

The initial version of the timeline was written by User:Sebastian.

Funding information for this timeline is available.

Feedback and comments

Feedback for the timeline can be provided at the following places:

- FIXME

What the timeline is still missing

Timeline update strategy

See also

External links

References

- ↑ 1.00 1.01 1.02 1.03 1.04 1.05 1.06 1.07 1.08 1.09 1.10 1.11 1.12 1.13 1.14 1.15 1.16 1.17 1.18 1.19 1.20 1.21 1.22 1.23 1.24 1.25 1.26 1.27 1.28 1.29 1.30 1.31 1.32 1.33 Froes, F.H. Titanium: Physical Metallurgy, Processing, and Applications.

- ↑ Roza 2008, p. 9

- ↑ Yanko, Eugene; Omsk VTTV Arms Exhibition and Military Parade JSC (2006). "Submarines: general information". Retrieved 24 July 2018.

- ↑ Stainless Steel World (July–August 2001). "VSMPO Stronger Than Ever" (PDF). KCI Publishing B.V. pp. 16–19. Retrieved 24 July 2018.

- ↑ 5.0 5.1 5.2 5.3 Aerospace Materials and Material Technologies: Volume 1: Aerospace Materials (N. Eswara Prasad, R. J. H. Wanhill ed.).

- ↑ Review of Extraction, Processing, Properties, and Applications of Reactive Metals: 1999 TMS Annual Meeting, San Diego, CA, February 28 - March 15, 1999 (Brajendra Mishra ed.).

- ↑ Froes, F.H. Titanium: Physical Metallurgy, Processing, and Applications.

- ↑ DK. 1000 Inventions and Discoveries.

- ↑ 9.0 9.1 9.2 9.3 Lütjering, Gerd; Williams, James Case. Titanium.

- ↑ Oshida, Yoshiki. Bioscience and Bioengineering of Titanium Materials.

- ↑ Roza, Greg. Titanium.

- ↑ Encyclopedia of Interfacial Chemistry: Surface Science and Electrochemistry.

- ↑ 13.0 13.1 13.2 Direct Reduction Processes for the Production of Titanium Metal: Report of the Ad Hoc Panel on Direct Reduction Processes for the Production of Titanium Metal of the Committee on Technical Aspects of Critical and Strategic Materials. National Research Council (U.S.). Materials Advisory Board. Division of Engineering.

- ↑ van Arkel, A. E.; de Boer, J. H. (1925). "Preparation of pure titanium, zirconium, hafnium, and thorium metal". Zeitschrift für anorganische und allgemeine Chemie. 148: 345–50. doi:10.1002/zaac.19251480133.

- ↑ Cardarelli, François. Materials Handbook: A Concise Desktop Reference.

- ↑ Holleman, A. F.; Wiberg, E. "Inorganic Chemistry" Academic Press: San Diego, 2001. Template:ISBN.

- ↑ 17.0 17.1 Titanium Powder Metallurgy: Science, Technology and Applications (Ma Qian, Francis H. Froes ed.).

- ↑ "World Firsts | British Pobjoy Mint". www.pobjoy.com. Retrieved 24 July 2018.

- ↑ 19.0 19.1 19.2 19.3 19.4 19.5 "Roskill Information Services: Global Supply of Titanium is Forecast to Increase". prnewswire.com. Retrieved 24 July 2018.

- ↑ Bush, Jason (15 February 2006). "Boeing's Plan to Land Aeroflot". BusinessWeek. Archived from the original on 9 April 2009. Retrieved 29 December 2006.

- ↑ "ISRO's titanium sponge plant in Kerala fully commissioned". economictimes.indiatimes.com. Retrieved 24 July 2018.

- ↑ 22.0 22.1 "Future of Titanium Powder Market in Global Industry 2018 -2028". theaerospacenews.com. Retrieved 24 July 2018.

- ↑ "Global Titanium Aluminide Alloy market is reach 640$ M by the end of 2025, growing at a CAGR of 21.0%". kxxv.com. Retrieved 25 July 2018.